Real-Time Results, Real-Time Impact

Digitize your manufacturing universe—factory, warehouse, and logistics—into a seamlessly orchestrated, data-responsive ecosystem. Our approach brings together MES, QMS, LIMS, AMS, WMS, eTPM, IES, CMS, and EMS systems with next-generation technologies, including edge analytics, IoT, digital twins, AI, GenAI, and immersive metaverse experiences.

Read more Read less

We advance every area, from Production Management to Quality, Process, and Asset Management, Maintenance & LEAN/JIT/JIS, Warehouse, Logistics, and Track & Trace, addressing end-to-end visibility from the shop floor through the supply chain, while being fully regulation-ready.

The modern factories we create drive outcomes through improved throughput, lower downtime, agile inventory, energy savings, and KPI breakthroughs that stand out. With scalable solutions proven across sites and sectors, we help leaders with intelligent manufacturing to shape their future.

Solutions

Digital Manufacturing

- GenAI Reporting

- GenAI Quality Prediction and Alert

- GenAI Machine Monitoring

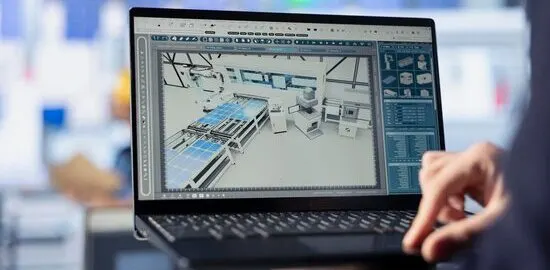

Digital Twin

- Production Twin

- Quality Twin

Assisted Operation

- AR / VR-based Machine Maintenance

- Virtual Production

- E–POKA YOKE Material Management

Manufacturing Operation Intelligence (MOI)

- AI and Advanced Data Analytics (insights)

- Visualization Tools (actionable intelligence)

Manufacturing Operation Management (MOM)

- Production Management System (PMS)

- Quality Management System (QMS)

- Manufacturing Execution System (MES)

- Computerized Maintenance Management System (CMMS)

- Laboratory Information Management System (LIMS)

- Warehouse & Inventory Management System

- Global Track & Trace (GT&T)

Industrial Internet of Things (IIOT)

- LITE MES – MOM

- Process Advisor

- Maintenance Advisor

- Plant Line Monitoring

- Quality Advisor

- Energy Monitoring

- E-TMP

Industrial Internet of Things (IIoT) Solution

- Integrated sensors, connectivity, data analytics, and automation

- Interconnected manufacturing environment

Factory Automation

- OT/IT Integration

- PLC and SCADA

- Edge Devices, CNS and DCS

- RFID, AGV, FMS and ATC

Services

Drive intelligent manufacturing with future-ready digital capabilities, boosting throughput, quality, agility, and sustainable growth across production networks worldwide.

Accelerators & Tools

SPECTRUM Platform

AI-powered MES/MOM accelerator delivering real-time production visibility, analytics dashboards, and intelligent decision-making across connected sites.

Factory Intelligence Suite

Integrates IoT sensor data with GenAI analytics to identify productivity losses and simulate improvements using digital twin models.

AR-Guided Workflows

AR/VR-enabled instructions layered onto MES workflows for visual guidance, reducing operator errors and increasing throughput.

Edge Quality Engine

AI-driven inspection at the edge detects defects instantly, seamlessly integrating with MES data flows for root-cause insights.

Connected Sustainability

Green engineering tool that monitors and analyzes water and energy usage in real time, using AI models to recommend adjustments and promote sustainability.

FAQs

1. How can real-time analytics improve factory operations?

Real-time analytics enables instant visibility into production, helping manufacturers quickly detect issues, reduce downtime, and optimize workflows. Manufacturers using real-time data solutions can see significant improvement in plant efficiency.

2. Why is digital twin technology valuable for modern manufacturing?

Digital twins create virtual models that simulate production and quality scenarios, allowing manufacturers to predict outcomes and prevent defects. Digital twin adoption can reduce time-to-market and quality-related costs for manufacturers.

3. What business benefits come from manufacturing IT integration and 24/7 support?

Integrated IT systems and round-the-clock support boost business continuity, minimize unplanned downtime, and improve decision-making. Aside from fewer production disruptions, manufacturers gain a stronger compliance posture.